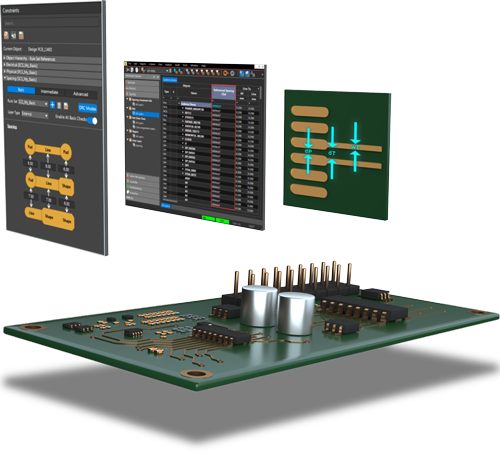

Constraint Management

Functional, Reliable, and Manufacturable Designs

Why PCB Constraints Matter?

No matter what type of board you’re designing, proper constraint definition guarantees that your design can meet performance, reliability, and manufacturing specifications. Over the years, miniaturization, regulatory compliance, signal speeds, and safety have made constraint management an essential part of the design process, setting the groundwork for ensuring the functional integrity of your printed circuit boards (PCBs).

The OrCAD X Constraint Manager’s common interface simplifies the constraint management process by standardizing rule capture and ensuring seamless synchronization between the schematic capture and PCB layout design environments. Electrical engineers and PCB designers can easily define and apply constraints throughout the design cycle for rules such as trace width, clearances, hole sizes, package to package spacing, annular ring dimensions, and more. With its object hierarchy and tabular interface, complex rule sets can be easily managed, validated, and cross-probed within the spreadsheet, making it easy to quickly inspect DRC results and increase the probability of first-time right design success.

Key Benefits of Effective PCB Constraint Management

Reduce Time-to-Market

Find and fix problems earlier in the design cycle

Improved Manufacturability

Comprehensive DFx checks covering design for fabrication (DFF), design for assembly (DFA), and design for test (DFT)

Signal Integrity and Performance

Identify and protect critical circuits from being victimized by incoming EMI

Seamless Collaboration

Easily communicate design intent and share constraints with all necessary stakeholders

Correct by Construction

Verify constraint compliance and ensure adherence throughout the design process

Regulatory Compliance and Standards

Meet regulatory standards by designing for EMC compatibility, susceptibility, safety, and functionality upfront

OrCAD X Constraint Management Overview

Learn how constraint driven design ensures that your designs are produced on schedule with first pass success.

OrCAD X Offers

Common Interface: The same easy to use constraint manager interface across schematic and PCB layout products.

Comprehensive Rule Support: Extensive support for electrical, physical, spacing, and manufacturing.

Constraint Groups: Easily apply multiple constraints to one or more objects using CSets, classes, groups, differential pairs, and regions.

Hierarchical Rules: Constraints specified at the top or bottom of the object hierarchy make it easy to control rule inheritance and override.

Constraint Reuse: Constraints can be exported and imported out of any design, simplifying reuse.

Defined Verse Actual: Real-time feedback provides target constraint values against actual implementation.

Start Your Free Trial Today!

Have additional questions? Click here to have our Cadence Channel Partners contact you.

© 2025 Cadence Design Systems, Inc. All Rights Reserved.