Design for Manufacturing

Design, Document, and Deploy

The Critical Role of DFM

Implementing DFx (design for assembly, fabrication, and test) standards is just one aspect of producing a manufacturable design. Following these standards allows you to refine the product design to optimize aspects such as size, materials, cost, sourcing, assembly, and overall functionality. The reliability and quality of your design ultimately depends on the manufacturing outputs, versioning, and consistency, including the detailed documentation for fabrication and assembly that support those outputs. To achieve first-pass success, effective design for manufacturing (DFM) practices are essential.

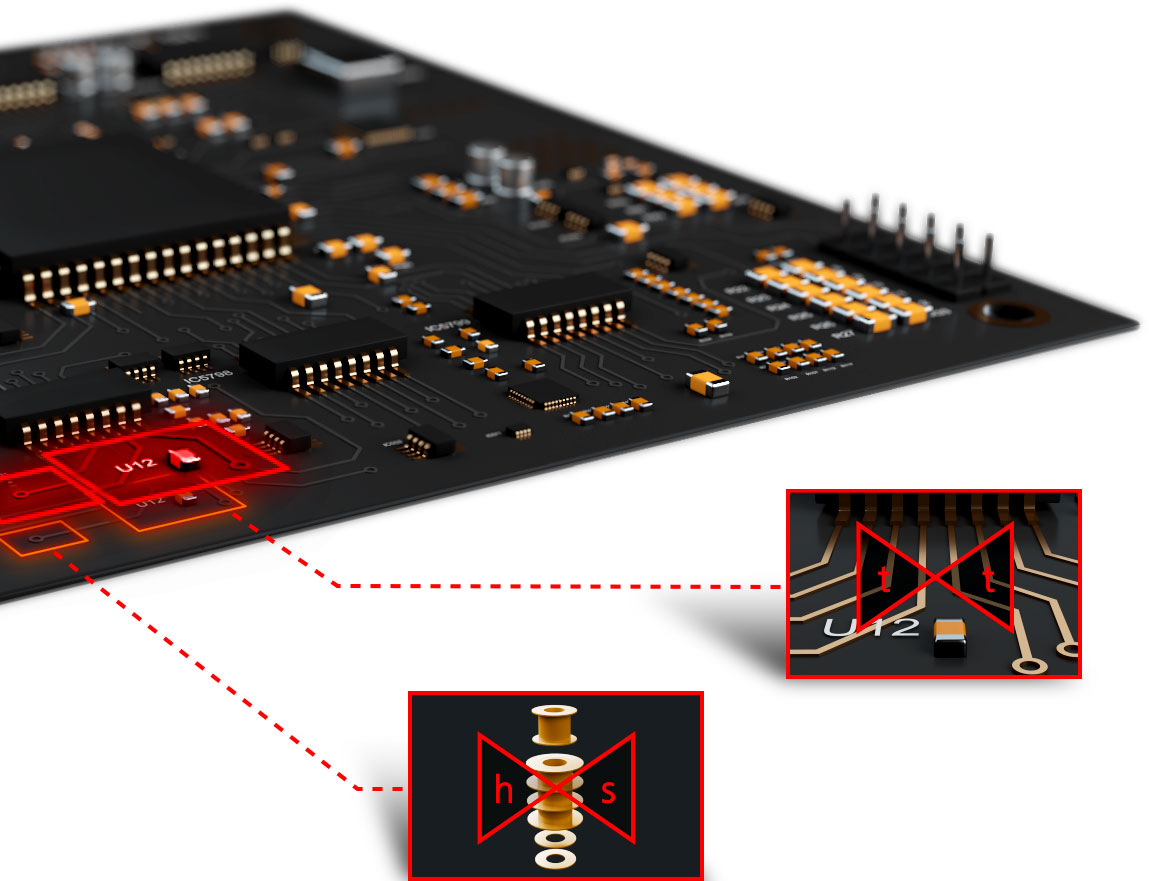

OrCAD X centralizes DFM constraints and left shifts DFM analysis directly into the PCB layout environment. As you place components and route your board, any manufacturing violations made appear on your canvas based on the constraints set, allowing you to resolve issues in real-time.

Key Benefits of Streamlined Manufacturing

Better Cost Reduction - Minimize production costs by reducing material waste, assembly time, and rework

Improved Quality - Prevent a range of issues or defects during production by optimizing product design and improving the manufacturing process

Enhanced Reliability - Optimize the shape, dimensions, and materials to improve its durability and reliability

Shorten Time to Market - Uncovering issues means rework and redesign, which wastes time, resources, and extends the product development cycle

Improve Production Efficiency - Avoid common manufacturing errors based on manufacturing process requirements and limitations

Key Features

Sharing and Collaboration

Easily work with contract manufacturers, design houses and consultants using shared workspaces through OrCAD X OnCloud.

Seamless Management

Version control all release content to ensure the right design version is matched to the output and documentation.

In-Design DFM

Rely on the robust set of real-time DFM checks within your PCB layout environment to ensure your designs are manufactured reliably and cost-effectively.

BOM Optimization

Validate and improve part cost, lead time, and alternate sourcing from a centralized dashboard.

Design for Fabrication

When you submit your designs for fabrication, you want success on the first pass. OrCAD X PCB Editor enables that with real-time fabrication, assembly, and test checks.

NEXT STEPS

Ready to get started with OrCAD X?

© 2025 Cadence Design Systems, Inc. All Rights Reserved.