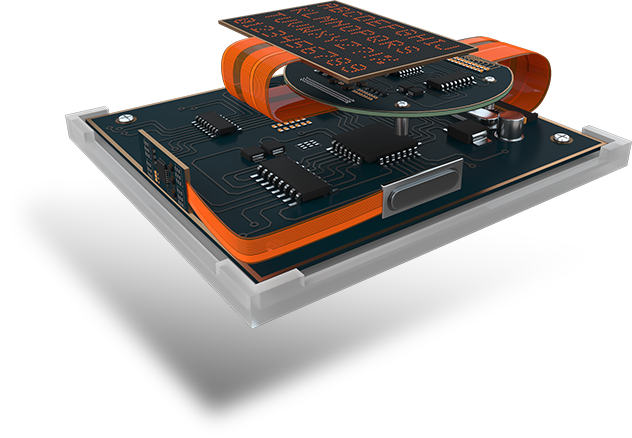

Build Reliable Rigid-Flex PCBs

Combining Flexibility with Robust Performance

Why Rigid-Flex?

Whether you’re developing wearable technology, aerospace systems, or automotive electronics, rigid-flex PCB design offers clear benefits for designing compact and reliable electronic solutions. While this hybrid construction that combines both rigid and flexible substrates within a single design offers many advantages, it presents several design challenges spanning mechanical, electrical, and manufacturing domains due to the combination of rigid and flexible sections on the same board.

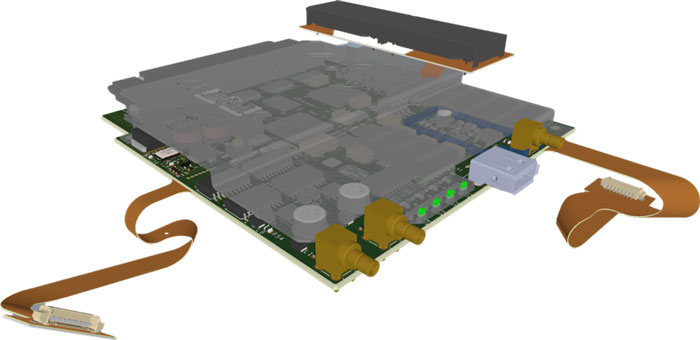

Initial design factors like the board outline, stackup, and material selection must be carefully considered to achieve primary functionality and ensure manufacturability. OrCAD X PCB Layout supports all aspects of rigid-flex design, including design definition, routing, validation, visualization, and mechanical integration. It removes the guesswork from the design process, guaranteeing that your design will function properly and be feasible to produce.

DRC Checks with Rigid Flex

Rigid-flex typically has strict manufacturing requirements to ensure the product can be built and reliably fold and bend. OrCAD X has real-time flex-based DRC checking to ensure your designs meet manufacturing demands.

Rigid-Flex Advantages in Modern Electronics

Reduced Size

Rigid-flex PCBs allow for three-dimensional layouts, enabling designers to fit more functionality into smaller form factors.

Enhanced Durability

Rigid-flex PCBs are made of polyimide of high thermal stability, allowing them to withstand high temperatures and demonstrate extreme resistance to ultraviolet and other radiation exposures, harmful chemicals, and harsh oils.

Enhanced Reliability

Rigid-flex designs minimize points of failure and improve overall reliability due to reduced solder joints, board-to-board connectors, and interconnect cables.

Streamlined Assembly

With fewer components to assemble and fewer interconnections to manage, the assembly process for rigid-flex PCBs is often more efficient compared to rigid assemblies.

Improved Signal Integrity

The controlled impedance characteristics of rigid-flex PCBs are ideal for high-speed signals and the flexible areas provide shielding for EMI and RF interference.

Reduced Cost

Due to their compact nature, rigid-flex PCBs require less material and fewer connections, resulting in lower assembly costs, maintenance expenses, and reduced failures, all while increasing product longevity.

Key Features in OrCAD X PCB Layout

- Contour Routing: Available in both single and multi-route modes - ensure routes easily follow the contour of curves defined in the flexible areas of the design.

- Inter-layer Design Rule Check: Provides the ability to check geometries between two different layers requiring special clearances or overlaps of materials, spacing, and design features.

- Signal and Power Integrity: Integrated with Cadence Sigrity technology, enabling robust analysis of power delivery to sensitive components and high-speed signals that pass from rigid to flexible PCB materials.

- Stackup by Zone: Multiple zones can be created using the cross-section editor to represent rigid-flex/rigid/flex PCB combinations.

- 3D Visualization: Provides a realistic board view of the final assembly, detailed rigid-flex bend visualization, and collision detection to validate component clearances in a folded state.

- MCAD Integration: Avoid unnecessary MCAD/ECAD iterations by providing an accurate definition of rigid-flex/rigid designs that can be passed on to mechanical design systems using IDX data exchange.

Start Your Free Trial Today!

Have additional questions? Click here to have our Cadence Channel Partners contact you.

© 2024 Cadence Design Systems, Inc. All Rights Reserved.